Emissions 2023

Below in this text is the data for our greenhouse (GHG) emissions calculated with CO2 equivalents (CO2eq), and the environmental footprint of our operations plus the nutrient release of nitrogen and phosphorus. Method and data for various calculation methods can be found here.

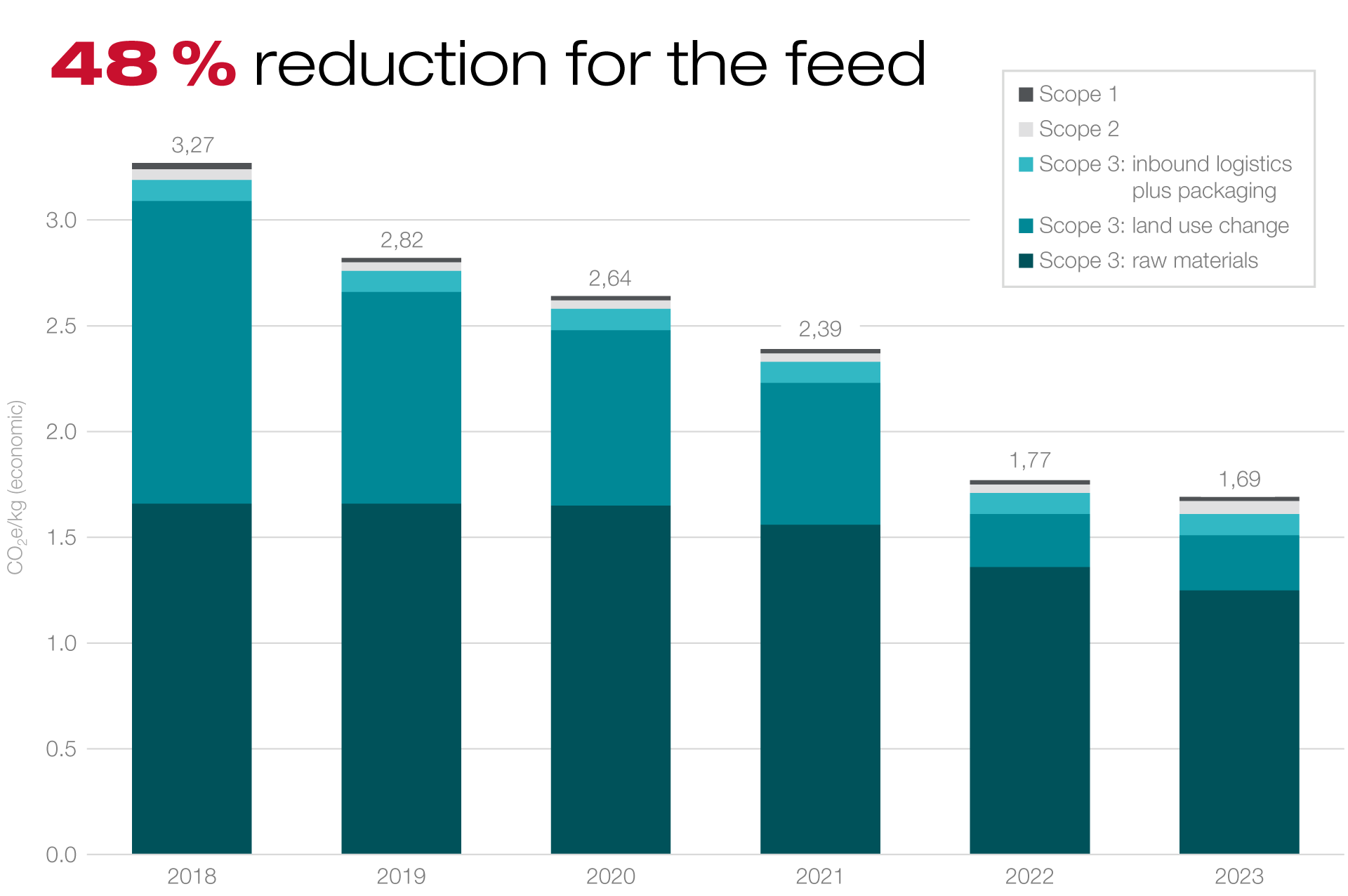

Skretting Norway still manages to reduce the emissions of greenhouse gases, but not at the same dramatic rate as previous years. The total emissions were reduced by 3.9 percent from 2022 to 2023. In the same period our production increased by 2.2 percent making it harder to reduce the total emissions. The Carbon footprint per kg feed was reduced with 4.5 percent from 2022 so that Skretting feed in 2023 had an emission factor of 1.69 kg CO2eq per kg feed.

New this year is that we will report according to the Forest, Land and Agriculture Science-Based Target-Setting Guidance (the SBTi FLAG Guidance). In 2024 we will update our SBTi targets to commit to the FLAG science-based targets.

The CO2eq reduction for 1 kg of feed at factory gate is reduced with 48 % from our baseline year 2018 to 2023. This is the major part of a salmon's scope 3.

From 2022 to 2023 our production increased by 2.2 percent making it harder to reduce the total emissions. The total emissions were reduced with 21,155 tonne CO2eq from 2022 to 2023 (3.9 percent). The Carbon footprint per kg feed was 1.69 kg CO2eq in 2023, a reduction of 4.5 percent.

Converting from natural gas to electricity increased emissions

We experienced a substantially shift from scope 1 to scope 2 in 2023. Scope 1 was reduced with 17 percent from 2022 to 2023, but scope 2 was increased with 59 percent for absolute emissions of CO2eq. The reason was that we transferred one of our boilers at the plant in Averøy from natural gas to electricity mid 2023.

To some this might seem strange, that emissions increase when you go from the fossil fuel natural gas to electricity. Especially since most of Norway’s electricity production is renewable energy coming from hydropower generators.

But Norway is part of the European electricity grid where electricity could be generated from fossil fuels like coal or gas. This results that electricity in Norway has a larger emission factor than natural gas since we have to use market-based calculation for scope 2 and not location-based emissions factors (as mandated by Norwegian governments). So our absolute emissions actually increases when we went from fossil natural gas to electricity.

In addition, the war in Ukraine has increased the use of coal and gas in European electricity production. This contributed to the increase of the emissions factor from 405 to 502 gram CO2eq per kWh from 2021 to 2022 (the latest official number that had to be used for 2023).

We still think it is the right way moving forward to convert our production from fossil fuel to electricity, even though we take “a hit” for the emission calculations now.

The days of low hanging fruits for Scope 3 reductions are probably over

The major reduction in scope 3 that was achieved from 2018 to 2022 where we picked the low hanging fruits, will probably be harder to replicate going forward. But we will keep up our efforts to reduce our scope 3 by working with our suppliers and consider emissions factors when formulating feeds.

Science based targets initiative (SBTi)

Through our mother company Nutreco, Skretting has committed to the science-based target initiative (SBTi) with a 30 % reduction of CO2eq for scope 1 and 2, and a 39 % reduction for scope 3 towards 2030 with 2018 as the baseline year. Several of Skretting Norway's customers have also made SBTi commitments, and our feed is their biggest GHG emission factor. To help our customers meet their targets for absolute GHG emissions— including their planned production growth for salmon and trout.

Our SBTi targets will soon be updated according to the new FLAG guidance.

The impact of feed

Feed plays an essential role in ensuring the health and wellbeing of farmed fish, and can greatly improve the efficiency of the aquaculture process. While gains are made in optimising feed efficiency, feed also contributes one of the biggest environmental impacts.

We will continue to improve our own operations (scope 1 and 2), but the main footprint of feed comes from the raw materials we use. So to further reduce our footprint our reduction strategy can be dived into three main areas:

1) Move to low carbon ingredients

We will replace ingredients with a high carbon footprints and high volume with low footprint ingredients by using circular ingredients, novel ingredients and ‘conventional’ low impact ingredients. This potential is already demonstrated in several cases.

2) Land use reduction

A major part of our GHG emissions is due to land use change, and this will be reduced. Land transformation affects carbon stocks and can result in carbon emitted that was stored in soil or plants (e.g. deforestation). That is why we have demanded that our suppliers of soy protein concentrate (SPC) from Brazilian beans must commit to a soy supply chain free from illegal and /or legal deforestation and conversion, using a cut-off date of August 2020, which they have all accepted.

We also encourage our suppliers to monitor and verify if their farmers have not done any deforestation or conversion for the past 20 years, as is the 20 year amortization period for the standardized calculation method: PAS-2050. This has been a major contributing factor for the massive reductions from 2018 to 2022.

3) Supplier engagement

We truly believe in supplier engagement to fight the climate crisis. That is why we will continue to engage with suppliers to collect and reduce GHG emissions in our supply chain. We will ask them to commit to the Science Based Target initiative (SBTi) because that will level the playing field since we will have the same goals using the same language. In addition we will push to get primary data for products so we can learn from each other and gain a deeper understanding of the supply chain. We will be a knowledgeable partner for both suppliers and customers, adding value to their reduction journey.

Carbon footprint of Skretting Norway's fish feed

Carbon footprint (CO2eq) per kg feed economic allocated with LUC (PEFCR standard)

| 2023 | 2022 | 2021 | 2020 | 2019 | 2018 | |

| Scope 1 (manufacturing process. direct GHG) |

0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.03 |

| Scope 2 (manufacturing process. indirect GHG)* |

0.06 | 0.04 | 0.04 | 0.04 | 0.04 | 0.05 |

| Scope 3 (value chain. indirect GHG)* |

1.61 | 1.71 | 2.33 | 2.58 | 2.76 | 3.19 |

| Total CO2eq per 1 kg feed GHG footprint at factory gate |

1.69 | 1.77 | 2.39 | 2.64 | 2.82 | 3.27 |

* A market-based calculation for electricity is used for every year

Carbon footprint (CO2eq) absolute tonne emissions, economic allocated with LUC (PEFCR standard)

| 2023 | 2022 | 2021 | 2020 | 2019 | 2018 | |

| Scope 1 (manufacturing process. direct GHG) |

10,850 | 13,082 | 13,211 | 14,203 | 13,843 | 14,906 |

| Scope 2 (manufacturing process. indirect GHG)* |

37,602 | 23,636 | 23,960 | 24,098 | 22,111 | 30,313 |

| Scope 3 (value chain. indirect GHG)* |

973,536 | 1,006,425 | 1,369,536 | 1,542,762 | 1,534,611 | 1,803,468 |

| Total absolute tonne CO2eq GHG footprint at factory gate |

1,021,988 | 1,043,143 | 1,406,707 | 1,581,063 | 1,570,565 | 1,848,687 |

* A market-based calculation for electricity is used for every year

The increase in scope 2 from 2022 to 2023 and the decrease in scope 1, is because one of our boilers at the plant in Averøy was transformed from natural gas to electricity mid 2023. Since we use market-based calculation for scope 2 and not location-based, electricity in Norway has a larger emission factor than natural gas. So our absolute emissions actually increases when we went from fossil natural gas to electricity.

FLAG Breakdown of scope 3 (CO2eq) per kg feed economic allocated with LUC. (PEFCR standard)

| 2023 | 2022 | 2021 | 2020 | 2019 | 2018 | |

| [Non-FLAG] Climate change fossil† |

0.71 | - | - | - | - | - |

| [Non-FLAG] Climate change land use change (LUC) |

- | 0.35 | 0.77 | 0.93 | 1.10 | 1.53 |

| [FLAG] Climate Change LUC†† |

0.35 | - | - | - | - | - |

| [FLAG] Climate Change Land management††† |

0.45 | - | - | - | - | - |

| [FLAG] Carbon removals and storage |

NA | - | - | - | - | - |

| Inbound logistics |

0.10 | 0.07 | 0.09 | 0.10 | 0.10 | 0.10 |

| Scope 3, Climate change kg CO2eq per kg feed |

1.61 | - | - | - | - | - |

† Excluding LUC, peat oxidation and land management emissions

†† Including peat oxidation

††† Non-LUC land-related emissions

Breakdown of Scope 3 (CO2eq) absolute tonne emissions, economic allocated with LUC, (PEFCR standard)

| 2023 | 2022 | 2021 | 2020 | 2019 | 2018 | |

| Raw materials [Non-FLAG] Climate change fossil‡ |

426,471 | - | - | - | - | - |

| Raw materials [FLAG] Climate Change LUC‡‡ |

160,749 | - | - | - | - | - |

| Raw materials [FLAG] Climate change - peat |

51,743 | - | - | - | - | - |

| Raw materials [FLAG] Climate Change Land management‡‡‡ |

268,108 | - | - | - | - | - |

| Raw materials [FLAG] Carbon removals and storage |

NA | - | - | - | - | - |

| Total raw materials absolute tonne CO2eq |

907,071 | 961,069 | 1,316,349 | 1,482,675 | 1,478,803 | 1,747,011 |

| Inbound logistics | 60,054 | 40,815 | 52,919 | 59,839 | 55,696 | 56,458 |

| Packaging | 5,945 | 4,147 | - | - | - | - |

| Air travel employees | 330 | 228 | 84 | 91 | - | - |

| Fossil car travel employees | 106 | 154 | 177 | 157 | 111 | - |

| Electric car travel employees** | 30 | 12 | 8 | 0 | 1 | - |

| Total Scope 3 absolute tonne CO2eq GHG footprint at factory gate |

973,536 | 1,006,425 | 1,369,536 | 1,542,762 | 1,534,611 | 1,803,468 |

| Outbound logistics | 23,901 | 23,706 | 22,160 | 22,883 | 19,828 | - |

| Total Scope 3 absolute tonne CO2eq including outbound logistics*** |

997,437 | 1,030,131 | 1,391,696 | 1,565,645 | 1,554,439 | - |

‡ Excluding LUC, peat oxidation and land management emissions

‡‡ Excluding peat oxidation

‡‡‡ Non-LUC land-related emissions

* A market-based calculation for electricity is used for every year

** Including fuel. vehicle production. maintenance and road emissions for fossil and electric cars with market-based calculations for electricity

*** Outbond logistics only covers delivery by boat

More data and method description

The European Union's Product Environmental Footprint Category Rules (PEFCR) requires carbon footprint to be reported with the economic allocation method including land use change (LUC). So, the tables above are our primary calculation method. We also use market-based calculation for electricity as this is the calculation Norwegian authorities demands from Norwegian power suppliers.

For your convenience we have included more data on a separate page.

- Method

- CO2eq economic allocated with LUC

- CO2eq economic allocated without LUC

- Explanation of CO2eq calculations method

Click here for method and more data

The environmental footprint of our operations

Skretting Norway operates in accordance with the Pollution Control Act (Act of 13 March 1981 No.6 Concerning Protection Against Pollution and Concerning Waste). Each operating plant has permits related to emissions to air, effluents to water and ground and handling of waste. Detailed description of permits for each operating plant together with historical records of emissions can be found here http://www.norskeutslipp.no/

Energy consumption, water and waste in operations

| 2023 | 2022 | 2021 | 2020 | 2019 | 2018 | Unit | |

| Energy consumption | 212.2 | 208.4 | 210.8 | 212.0 | 217.7 | 229.4 | kWh/tonn |

| Water withdrawal | 350.4 | 341.5 | 345.3 | 385.0 | 472.6 | 532.7 | liters/tonn |

| Waste generation | 4.3 | 4.3 | 4 | 4.7 | 6.1 | 5.7 | kg per tonne |

Absolute CO2eq emission per energy carrier from operations (tonne)

Through our mother company Nutreco, Skretting has committed to a 30 % reduction of CO2eq for scope 1 and 2 in compliance with the science-based target initiative (SBTi) with 2018 as our baseline year. The reduction from 2018 to 2022 is 19 % for scope 1 and 2.

| 2023 | 2022 | 2021 | 2020 | 2019 | 2018 | |

| Natural Gas | 3,219 | 3,480 | 3,488 | 4,654 | 4,423 | 4,816 |

| Diesel | 288 | 283 | 267 | 293 | 254 | 269 |

| LPG | 1,475 | 1,372 | 1,365 | 1,387 | 1,227 | 1,238 |

| LNG | 5,868 | 7,947 | 8,091 | 7,869 | 7,939 | 8,583 |

| Electricity* | 37,602 | 23,636 | 23,960 | 24,098 | 22,111 | 30,313 |

| Absolute carbon emission (tonne) | 48,452 | 36,718 | 37,170 | 38,301 | 35,953 | 45,219 |

* A market-based calculation for electricity is used for every year. Click here for a more detailed explanation of market-based vs. location-based calculation.

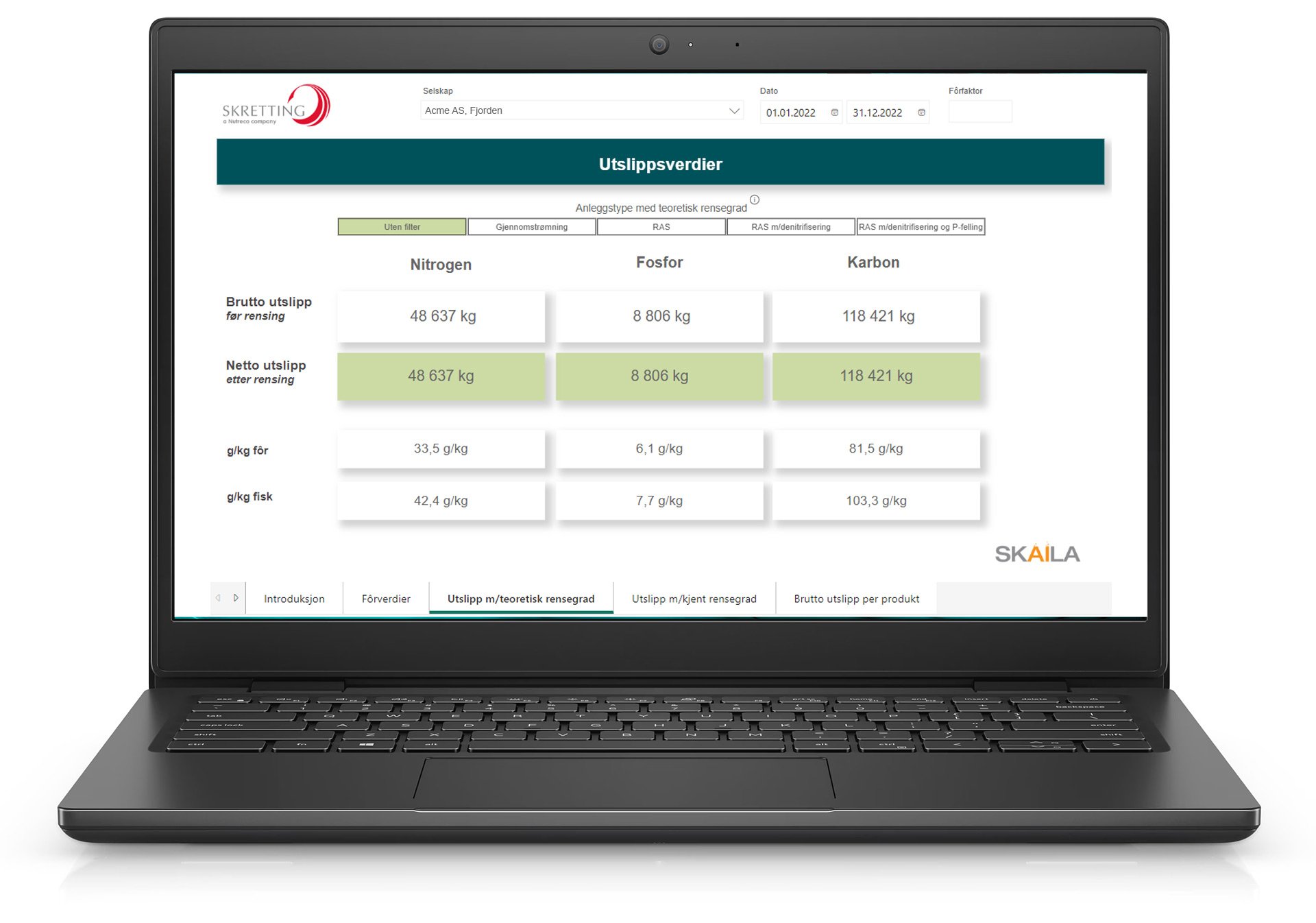

Nutrient release

Nutrients such as phosphorus and nitrogen are essential for life and these elements occur naturally in the water column of both fresh and marine environments. In the environment they function as nutrients for algae growth.

Skretting's nutrient release calculator offers data for customers, specific feeds and/or for individual fish farm locations based on the delivered feed.

Skretting has implemented a new nutrient release model that gives our customers emission values for their own feed, even for their own specific locations. We calculate emissions for nitrogen, phosphorus and carbon. The tool is avaliable on our client net.

Disclaimer

The provided carbon footprint data are based on internal calculations following the core guiding principles of the standard PEFCR Feed for Food Producing Animals (2018), but are not based on fully compliant PEFCR studies. Although Skretting has taken care to ensure that the information contained herein is as accurate as possible and up to date, Skretting does not warrant the accuracy, reliability or completeness of the information. The values have not been externally verified. The information provided is for informational purposes only and is intended for internal business use only. The reader is solely responsible for any interpretation or use of the material contained herein. The footprint data are subject to change (e.g. due to ongoing database development or better supply chain information). Furthermore, cradle-to-gate footprint values are not allowed to be used for comparison or comparative assertions among each other or with other feed footprint data in accordance with international LCA standards. Animal feed is an intermediate product in the food production chain and the footprint attached to it only reflects part of the life cycle. Without considering feed performance/ functionality and downstream impacts, comparison is neither allowed nor meaningful.