Nursery system existing in India but was not in much focus till 2016 and since then attention been given to it. In the nursery phase, it is possible to manage higher stocking densities and increase the number of crops per year in shrimp farms

Nursery System- An emerging concept to mitigate risk in shrimp culture

Nursery systems are receiving increased importance in shrimp culture in India. In this article our experts highlight how profitable shrimp culture can be carried out with the help of nursery and how it can lessen the burden on both culture and ecosystem, besides lowering the risks of outbreaks and losses.

Introduction:

The nursery phase for shrimp production was first introduced in 1974 (Parker et al., 1974)

Although, in the 1990s most farmers had reverted to direct stocking, at present again with L.vannamei boom and multiple emerging and new disease threats the use of nurseries is on the rise.

Because a nursery phase can intersect the disease transmission and contributes to the rapid growth of the cultured organisms.

Nursery system existing in India but was not in much focus till 2016 and since then attention been given to it. In the nursery phase, it is possible to manage higher stocking densities and increase the number of crops per year in shrimp farms

Benefits of Nursery Systems:

Stocking post larvae (PL) after a nursery phase (usually >PL45) instead of PL10-12 direct from hatcheries will reduce the duration in the grow-out ponds by 20-30 days and feed conversion ratio (FCR) by 10-30%. In Mexico and Asia, this is now one of the strategies used to mitigate early mortality syndrome (EMS) by stocking larger size post larvae into grow-out ponds.

Shrimp nursery systems can provide several advantages over direct stocking to include: More efficient facility utilization, Greater Bio security, water quality, feed, and feed management, Supply of larger & robust shrimp with high compensatory growth, and overall better survival of shrimp, Decreased grow-out cycle with more crops per year and most importantly serve as primary quarantine period when needed.

Phases in Nursery system:

Shrimp production can take place in single-, two-, or multi-phase systems.

In a single-phase system, PL are stocked directly into grow-out tanks and stay there until the harvest.

In two and three-phase systems, grow-out tanks are stocked with juvenile shrimp cultured previously in other tanks under high stocking densities - a stage referred to as the nursery phase. The three-phase system has its own benefits in the supply chain by having constant control of water parameters and health of shrimp. Also chances of better feeding efficiency.

The whole concept of nursery revolves around producing strong and healthy post larvae/juvenile which have been acclimated almost to the pond environment. As a result, producer can get a better survival, less disease risks, increase in crops which in turn helps the whole chain of shrimp production to be on an incremental path.

However, all of this can be achieved only with the use of proper technology and with full control of the culture system. In poorly constructed or managed nursery systems, low survivals may result, and weak animals are likely to be transferred to ponds.

Nursery system design and operation:

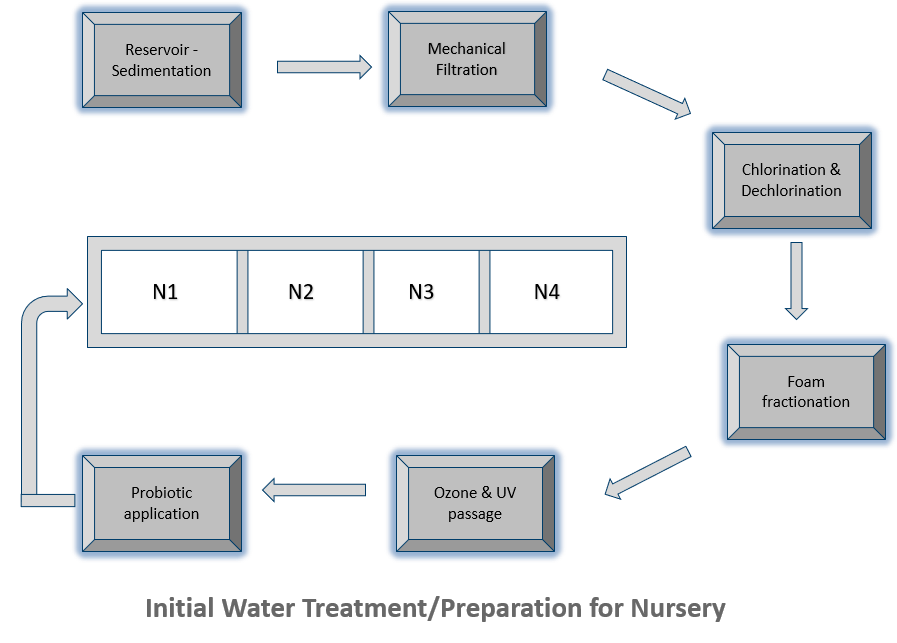

Initial Water Treatment/Preparation

Use of Sedimentation, Mechanical Filtration, Chlorination-De chlorination, Foam Fractionation, Ozonation, UV

The ideal location for a nursery is near growout farm with an accessibility to high water quality. To minimize the risks of power failures, it is advisable to use power back up sources and the travel distance to the farthest pond in the farm also to be considered.

Nursery tank shape can be circular, square , rectangle etc., BUT the round shape tanks gives more benefits than the rest, such as – easy to manage, uniform distribution of water and aeration, central drain system with an accumulation of waste which can be siphoned easily.

Basic parameters to monitor in Nursery System:

Temp ©, DO (mg/L), Alkalinity (mg/L), NH3- N (mg/L), TAN (mg/L), NO2-N (mg/L), NO3-N (mg/L), Average weight ( g ), Biomass (kg/m2) and (kg/m3)

Nursery management

In general shrimp are usually stocked in nursery tanks as PL-8 or PL-10. Whereas in multiphase, 5-day old PL`s can also be stocked. Initial stocking densities vary from 15-25 PLs per liter in multiphase and 4-12 in two phase and the normal survival rate would be > 95 percent in both the cases (depends on other criteria).

Prior to stocking, nursery tanks, hoses and air stones are disinfected with sodium hypochlorite at 20 ppm, brushed and washed with running water, and dried for 24 hours. After filling the tank with seawater, inorganic fertilizers are applied. Phytoplankton inoculation can be used when faster blooms are required.

PLs need to be acclimated to water pH, salinity and temperature in 1,000-L fiberglass tanks before stocking in the nursery tanks. When acclimation exceeds more than two hours, feed must be provided.

During the nursery stage, shrimp are fed high-quality starter diets with >40 percent or more crude protein content and less than 800-μ size. Larval diets are used to minimize the risk of disease transmission. Dried feed is broadcast in the first days after stocking and then delivered in feeding trays.

General water exchange should be done not more than 10 percent a day over the first week of culture to maintain a high phytoplankton biomass. After wards, water can be exchanged up to 30% daily. Wastes on tank bottoms are to be siphoned away.

In nursery system the most critical part is the transfer of juveniles to grow out ponds. Before transfer, the health and digestive tract are to be checked.

Management of NURSERY is a key for successful operation; and adequate tank preparations (cleaning, disinfection, probiotic applications) are crucial to avoid Vibrio & Pseudomonas outbreaks in the nursery tanks. Probiotics are added during tank preparations & during production, with efforts to identify optimal blends to increase survival, reduce Vibrio& Pseudomonas.

Control of water quality and feeding

The main criterion is control of water quality. Probiotics are applied according to the target; the protocol of the different probiotics is adjusted depending on the biomass, water quality and animal health conditions. The objective is to maintain optimal conditions in order to keep the animal healthy for it to express the compensatory growth potential when transferred.

In the case of feeding, lower quality feeds with fines will affect water quality and shrimp performance. As such, higher quality hatchery feeds with less fines are most desirable.

Especially feeds with a 42% crude protein and high energy feeds are fed at 2-hour intervals. Feed amounts are adjusted depending on feed trays, water quality and animal growth.

Use of Limited Discharge Practices:

Studies showed that L. vannamei can be raised with reduced water exchange without adverse effect on its growth, survival and yield. In limited discharge systems, shrimp depend on commercial feed as the primary source of food, use of high-quality feed with adequate management can significantly improve shrimp performance, water quality and the Economics. Microbial communities in these systems can serve as a source of single cell protein that provides supplemental food source.

Conclusion

The reintroduction of shrimp nurseries in many South-east Asian countries is an important step in managing the new normal for the shrimp industry. The emergence of new diseases will not stop and the industry has to adapt to current and future diseases through adapting management practices and focusing on quality feed and feed supplements to ensure robust animals. Shrimp nurseries are already being implemented on a commercial scale by farmers in Thailand, Vietnam, Indonesia and in India it is on a progressive mode.

Farmers setting up shrimp nurseries should focus on using high quality diet and feed supplements that are specially designed to be used at this stage of shrimp production. Must keep in mind that – DO NOT COMPROMISE ON QUALITY.

Nursery functions as temporary controlled reservoir where shrimps are allowed to a slow acclimation to the farm conditions. These systems reduce the exposure of shrimps to potential threat (disease, stress factors etc.,) and allow early detection of any health-related issues.

Nursery - If not managed properly, the following issues can arise:

Nursery systems also have a few downsides, including greater infrastructure investment (higher construction costs than conventional pond systems) higher operational costs, and increased labor requirements as it requires trained biologists. As stocking densities increase and water exchange decreases, higher organic loads increase the risks to adequate water quality and animal health. And there is increased stress to animals due to more handling and transferring, which can increase susceptibility to several diseases. Therefore, proper management of nursery systems is a critical prerequisite for their success.